Driven by our curiosity, admiration and respect for nature, we embrace her power to close material cycles.

Since the industrial revolution mankind has exploited nature without taking the ecosystem boundaries into account. Although this has brought us incredible wealth, over time this has brought us further and further away from a planetary equilibrium. This is not sustainable…

At Paques Biomaterials we believe that prosperity and sustainability can go hand in hand. Our biomaterials are naturally produced using renewable resources. In harmony with nature.

The Paques Biomaterials team has developed its own technology for production of PHA polymers using circular feedstocks for over 10 years. The PHA polymers are produced by natural bacteria that use the polymer as food reserve, just as humans use fat. These bacteria can accumulate PHA up to 90% of their cell weight, and they can do this while consuming organics in a wide variety of residual streams, such as industrial wastewater or solid organic wastes.

The proprietary technology of Paques Biomaterials can harness this amazing natural process and accumulate PHA in biomass effectively, stabilize its quality and purify the polymer, producing our high quality Caleyda. Caleyda can be tuned for a wide variety of uses while always keeping its most crucial property: it is fully biodegradable in natural environments.

In 2011, Paques joined forces with the Technical University of Delft (TUD) to further develop their new concepts to produce PHA polymers using a mixed culture approach. This mixed culture approach is ideal to use with residual feedstocks, as sterilization procedures are not required. Since then we enlarged our R&D network in Europe and we keep on developing new technologies for PHA production using mixed cultures, counting currently with a total of 7 patents.

Since 2012 we have performed 7 successful pilot projects for PHA biomass production using different waste streams as feedstock: industrial wastewater (candy factories & paperboard factories) and source separated municipal solid waste. We have also piloted different PHA rich biomass production concepts, widening our range of process options to better suit different cases.

We have also piloted our PHA extraction process using green solvents. A process that is key to generate Caleyda® with fine-tuned properties.

After four years of research, the technology had proved so successful that it could continue under its own entity, leading to the establishment of Paques Biomaterials.

Five Dutch water boards have agreed to contribute financially to a demo plant for PHA biomass production in Dordrecht, Netherlands. This demo plant will be built within a consortium between Paques Biomaterials, HVC, Aquaminerals, STOWA and the five waterboards.

Paques Biomaterials was carved out from its mother company Paques. Paques is a global company focusing on selling industrial wastewater and biogas treatment installations but for the PHA production technology a different business model and different visions were seen as key to scale it up and bring Caleyda® to the market. In 2021, Paques Biomaterials became fully independent from Paques (at legal and shareholder level) to follow its own path and bring Caleyda® to the market.

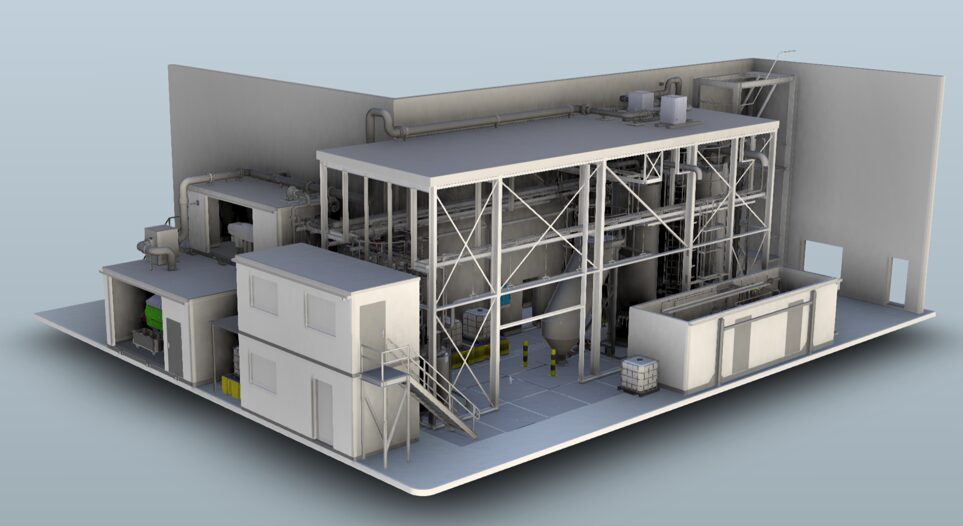

In 2022 we started operations of our first demonstration plant for PHA biomass production in Dordrecht, Netherlands. This Demo plant is part of the project PHA2USE, involving a consortium between Paques Biomaterials, HVC, Aquaminerals, STOWA and 5 Dutch water authorities. This unique Demo facility can be used with different PHA biomass production approaches and use different circular feedstocks, brought in from other locations.

Paques Biomaterials is currently designing and engineering its own PHA extraction Demo plant which will be operational in 2024 and located in Emmen, Netherlands, completing the full demonstration of the technology to produce Caleyda®.

The Research Extraction Facility (R.E.F.) is engineered to help us develop our extraction technology efficiently. We extract only a few grams in our laboratory, but we extract over 50 kilos per run in our pilot plant in Emmen. We were looking for an intermediate solution that gave us the flexibility to do quick tests.

Our colleague Chris Vermeer developed and engineered the R.E.F., which will extract a few kilos per run. Exactly enough to allow us to perform serial test runs, extract different grades of PHBV, and support us in our bold creativity to try new ideas.

The Caleyda® pilot plant will start extracting 50 kilos of Caleyda per run by the end of 2024. This will help us scale up our technology, prepare for the full-scale plant, and, in the meantime, provide material for application development.

The PHA biomass full scale plant is already under development. It will produce biomass to be further processed into products or Caleyda®, in its future full scale PHA extraction plant

With also the full scale extraction plant in Emmen the production of Caleyda will start!

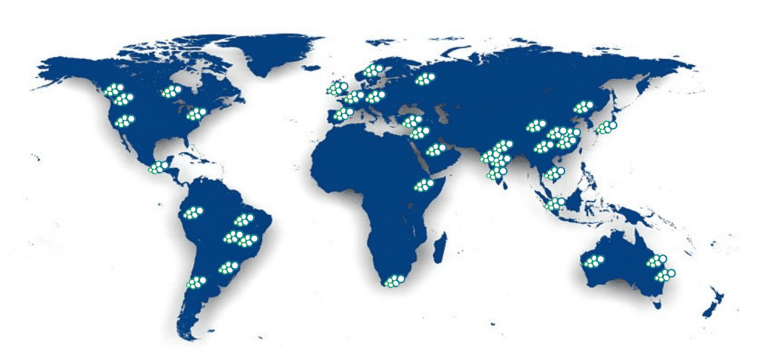

Once the business case is firmly established, Paques Biomaterials has global ambitions. Besides expanding by building new PHA production facilities, Paques Biomaterials will also license its technology to strategic partners in other regions of the globe, accelerating the expansion of Caleyda!

Global Senior Executive, Renewable Chemicals

Babette Pettersen

Supervisor

Kees Akkerman

COO, Corbion

Jacqueline van Lemmen

Research & Development

Prof. dr. h.c. Ir. Mark van Loosdrecht

Plant operations

Drs. Sjoerd Visser

Polymer industry

Mr. Ruud Rouleaux

Polymer Materials Specialist

Prof. dr. Stephen J. Picken

Paper & Biobased Industry

Dr. Ir. Annita Westenbroek

Process upscaling

Ir. Joop de Rooij