Paques Biomaterials develops a biodegradable alternative to plastic by using organic side streams.

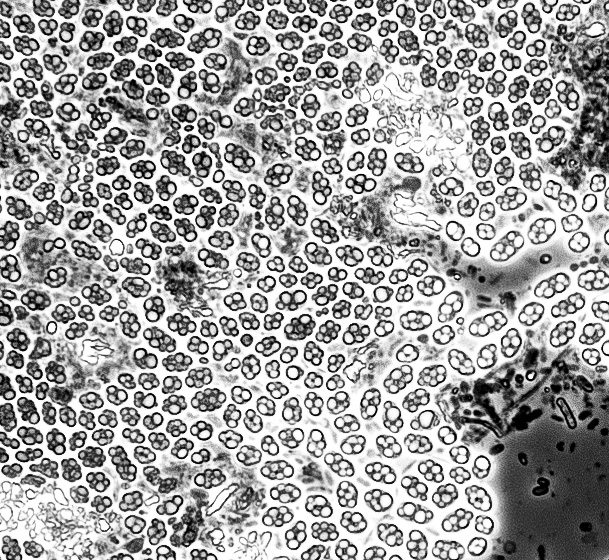

We developed a technology for microbes to produce a biopolymer (PHA) from organic residual streams.

Our technology doesn’t modify bacteria genetically and we use no fossil resources.

This is the start of a global, new circular chain to produce a natural alternative to plastic that is naturally biodegradable in all environments without leaving harmful microplastics behind.

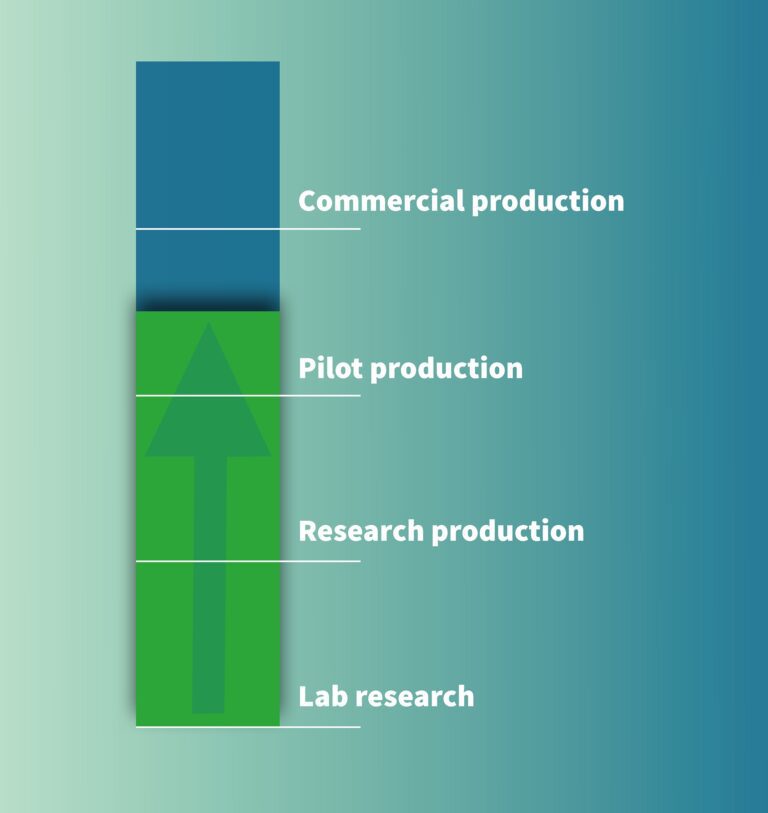

To develop a high-quality and tunable biopolymer, we have to test different grades of PHA. We extract only a few grams in our laboratory but over 25 kilos per run in our pilot plant in Emmen. So, we needed an intermediate solution that would give us enough material to do quick tests.

Our colleague Chris Vermeer developed and engineered the Research Extraction Facility, which will extract a few kilos per run. Exactly enough to support us in our bold creativity to try new ideas.

To produce Caleyda® we are engineering two technology processes:

1) the microbes producing the PHA in mixed cultures

2) extracting the biopolymer from the biomass.

The first technology is already proven in a demo plant. The first full-scale plants are already under development.

For the second technology we are building the pilot plant which will be operational by the end of 2024. The first steps towards commercial production are already taken.

We develop a naturally biodegradable biopolymer with the brandname Caleyda®.

Caleyda ® stands out to other biopolymers because: